Discover our Cell Testing Solutions

We offer Battery materials and Cell testing services:

-

Coin cell fabrication and Electrochemical testing (Specific capacity analysis, EIS, dQ/dV, Cyclic voltammetry, GITT, LSV, LSA etc)

-

Materials (Cathode and Anode) testing (Electrode slurry preparation, Slurry Viscosity, Moisture analyser, Slurry doctor blade coating, drying and calendering)

-

Pouch cell fabrication – Single and Multilayer

-

Long term cell cycling

-

EIS interpretation

Available Facilities:

- High Purity Argon Gas filled – Four Port Arrays Glove Box

- Electrochemical Workstation (EIS Analyser – Admiral Squidstat plus)

- Multichannel Cycle tester (High current version)

- High temperature furnace (up to 1200 Deg.C) – Multistep Micro-controller programmable – imported

- High Temperature Vacuum Oven

- High temperature Drying Oven

- Viscometer

- Liquid Electrolyte Conductivity analyzer

- High Energy Planetary Ball Mill

- Planetary Electrode Slurry mixer

- Doctor blade vacuum coating machine

- Twin roller calendering machine

- Ultrasonic Spot Welding machine

- Resistance Spot Welder

- Pouch cell external sealing machine

- Pouch cell vacuum sealing machine (Operating inside Glove Box)

- Four probe testing machine with temperature Solid Electrolyte testing

- Spin coater

For more information, Please contact:

Dr J. Malathi, Ph.D,

Research Scientist

email: info@inventus.in

Our Business Focus

Under the new energy paradigm with the tagline “Empowering the Future with Solid-State Battery Innovation,” Inventus aims to address the challenges posed by traditional Li-ion batteries—namely safety, limited energy density, charging time, and waste disposal—by offering a groundbreaking solution: Solid-State Batteries (SSBs). Recognized as the “holy grail” of EV batteries, SSBs are deep-tech products that promise significant advancements. With its indigenously developed technology, Inventus is poised to make a substantial leap in advancing the cell manufacturing ecosystem in India, serving as a one-stop technology shop for all new-age lithium battery cell production needs.

Inventus Battery Energy (IBE™) Technologies (P) Ltd is a unique startup specializing in new energy battery technologies, including Cathode-Active Materials (LFP, LMFP, NMC, and LNMO CAMs), LiPF6 electrolyte manufacturing know-how, and ACC manufacturing technology formulations (LFP and NMC chemistries). Inventus holds several unique patented processes and offers licensing to manufacturers.

The company provides clients with turnkey solutions for LIB cell manufacturing (MWh and GWh plants) and supports the commercial-scale production of raw materials such as Pre-CAM, CAM, and LiPF6 liquid electrolytes (ranging from 200 to 20,000 liters per day).

Committed to supporting the national mission on Advanced Cell Chemistry (ACC) and Battery Energy Storage, IBE offers indigenous patented advanced battery cell technologies, including cell chemistry know-how and process formulation, bundled with comprehensive turnkey project support. Specifically, IBE™ meets India’s energy storage industry needs by offering complete end-to-end turnkey solutions that include CAPEX, OPEX, ROI, plant design, and customization.

Our turnkey solutions encompass end-to-end process know-how, factory infrastructure design, machinery supplier recommendations, and CAPEX and OPEX for giga factories. We provide well-rounded consultancy services for battery risk mitigation, addressing fire incidents, and assisting with DFMEA for Li-ion cell manufacturing industries.

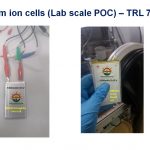

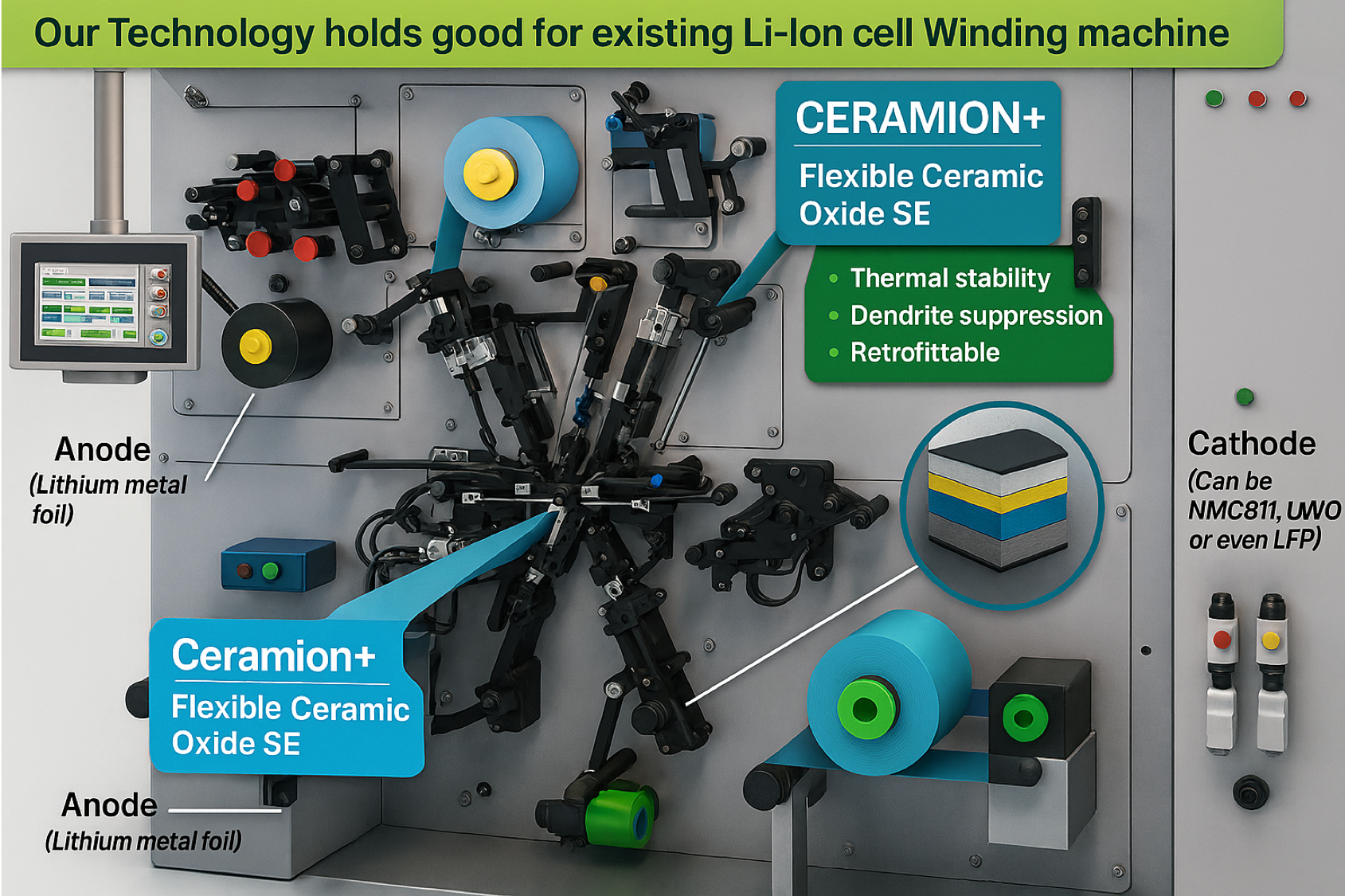

Our cutting-edge solid-state battery technology has reached TRL 8, and our flexible ceramic oxide tape cast electrolyte technology facilitates roll-to-roll cell manufacturing, reducing the need for capital-intensive machinery. Inventus welcomes joint development partners (JDP) and joint venture (JV) equity-based business propositions for its disruptive Protected Lithium Metal Cassette (PLC) anode-based all-solid-state battery technology, currently at TRL 8. Our ASSB, powered by the flexible Ceramion+™ technology, is designed to seamlessly integrate with existing Li-Ion cell manufacturing infrastructure. This innovative solution eliminates the need for specialized equipment or applied stake pressure to operate the cell or battery system—making it a standout feature and a key USP of our Ceramion+™ technology.

Major Services

We offer the following technology services to LIB Cell manufacturing industries as part of the complete industrialization drive in India.

- Know-how licensing of Cell Chemistry and Turn-key solutions to LIB Cell Manufacturing Companies (All Form Factors).

- Know-how licensing and Turn-key solutions to Pilot and Commerical scale manufacturing of Li-CAMs (LFP,LFMP, NMC, LCO and LMO) manufacturing.

- Know-how licensing and Turn-key Solution to LIB non-aqueous LiPF6 and LiFSI Liquid Electrolyte Formulation and additives.

- Project Planning, CAPEX, and OPEX

- M-factory and G-Factory Plant design, Construction support, Dry roo and Clean room design of LIB cell manufacturing environment, Equipment identification, Raw materials supply chain etc

Our Expertise

-

Rich Experience (over 30 years) in cell design & development

-

Development & optimisation of cell chemistry (cathode materials, anode materials).

-

In-depth knowledge of Li-ion battery cell operation, performance and failure modes.

-

Experience in different physical and chemical characterisation tools for AAM and CAM powders, fabricated electrode, and various types of prototype cells.

-

Unique Slurry powder mixing sequence

-

Slurry viscosity optimisation (visco-elastic properties and pH) and resistivity of the slurry

-

Electrode coating and drying sequence for AAM and CAM