Ceramion+™ Flexible Li+/Na+ Solid Electrolyte Technology Developed by INVENTUS

Inventus Battery Energy Technologies Pvt Ltd is proud to announce its selection for the prestigious TDVC project by NRDC, DSIR, Government of India. This significant achievement highlights Inventus’s leadership in next-generation energy storage solutions and advances the scaling of its patented All-Solid-State Battery (ASSB) technology.

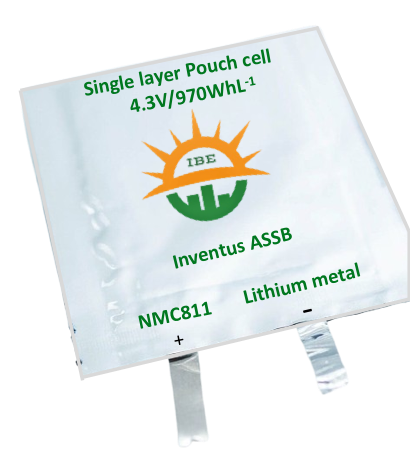

At the core of this innovation lies the groundbreaking PLC (Protected Lithium Metal Cassette) anode, integrated with our proprietary Flexible Ceramic Solid Electrolyte. Together, they represent a global-first breakthrough in battery innovation, redefining industry standards for safety, efficiency, and performance.

As Inventus progresses toward commercial-scale production, this state-of-the-art ASSB sets new performance benchmarks with:

- An impressive cycle life exceeding 6,000 cycles,

- An energy density of >400 Wh/kg,

- A single-cell nominal voltage of ~4.8V, and

- A rapid charging capability achieving 0-80% SOC in under 15 minutes.

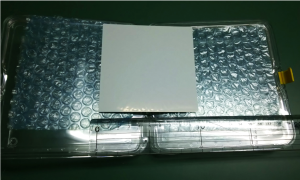

Inventus’s Ceramion+™ technology further enables robust cell formations in both pouch and cylindrical form factors. Impressively, this innovation is fully compatible with existing Li-Ion cell manufacturing machinery, facilitating seamless adoption of our anode-less Lithium Metal ASSB technology, thanks to the flexibility of the Ceramion+™ membrane ceramic solid electrolyte.

This milestone underpins Inventus’s mission to pioneer sustainable, high-performance energy storage solutions and reinforces its commitment to reshaping the future of battery technology.

TOP 50 COMPANIES DEVELOPING SOLID STATE BATTERIES

Inventus is one of the top 50 companies in the world developing Solid State Batteries as recognised by batterydesign.net

https://www.batterydesign.net/battery-cell/cell-manufacturers-and-logos/solid-state-cell-companies/

TECHNOLOGY BRIEF

EVs are witnessing a growing demand as several countries around the globe have set deadlines for zero-emission mobility via various subsidies for OEMs and EV users, despite the lack of charging infrastructure and battery production capacity against demand. In the present scenario, lithium-ion batteries (LiBs) are widely used as the power source for EVs. Of late, increasing the energy density and safety of batteries has become one of the major concerns of the battery community driven by the ever-growing markets for battery-powered electric vehicles. Hence, industry players (both battery companies and passenger vehicle producers) are hurried to pursue high energy density (Wh/kg) and lower costs ($ per kWh) battery technology along with safety as a paramount factor. Strategies include utilizing Si anodes and leapfrogging to solid-state battery (SSB) – Advanced Chemistry Cell (ACC) technology.

Considering these real world problems that are centered on advanced batteries for instance, the traditional Li-Ion cells are suffering from thermal runaway problems when abused inadvertently leading to adverse safety issues. These problems are totally eradicated while using ASSBs. In general, ASSBs are made of either inorganic substrates (ceramic oxide and sulfides) as well as Li+ doped polymer membranes) as SEPARATOR CUM ELECTROLYTE in a solid form, offering multiple advantages such as high ionic conductivities (of the order of mS/cm) at room temperature (as good as LiPF6 liquid electrolytes), very good electrochemical stability at high working voltage (~5V vs. Li+/Li), stable at high temperature at least up to 120 deg.C, mechanically robust, flexible, longer cycle life (>5000 cycles with 90% capacity retention), Cell design advantage etc.

All-Solid-State batteries (ASSBs) with lithium metal anode are becoming imperative due to growing concerns involving environmental issues arising from solvent-based electrolytes and the stringent emission norms worldwide. ASSBs hold great promises owing to the following reasons:

- Replacing the flammable carbonate-based electrolyte in conventional Li-ion batteries with a non-flammable solid electrolyte (SE) reduces battery fire risk.

- Replacing a graphite anode (~372 mAh/g) with a lithium metal anode in conjunction with a ceramic solid electrolyte (CERAMION+ )making a battery cell to be a TRUE All-Solid State making ASSBs to be compact offering increased volumetric energy density (~50% higher).

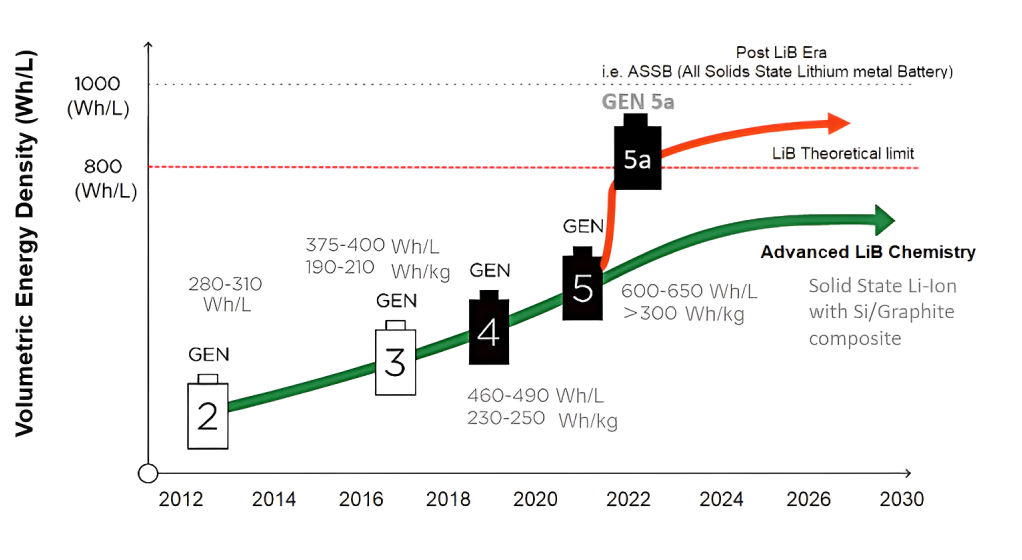

Hence, the ASSBs offers more volumetric energy density (Wh/l), more beyond the theoretical limits of traditional LIBs. The figure below illustrates the taxonomy of lithium-containing battery systems showing the evolution of ENERGY DENSITY metrics over the years with different battery chemistries known hither to.

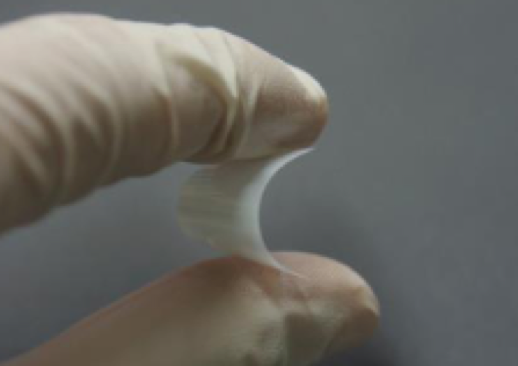

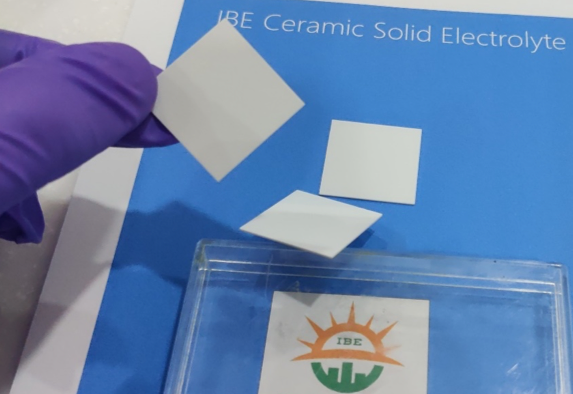

Our Flexible Ceramic Solid Electrolyte membrane having a thickness of 25µm (analogous to Celgard 2325 Tri-layer separator membrane) supports ROLL-TO-ROLL Cell manufacturing

USPs of PLC anode enabled ASSBs developed by Inventus Battery Energy Technologies (Indian Patent granted # 385777, Dec. 2021):

- Flexible as in Celgard PP/PE/PP separator membranes thus supports Roll-2-Roll manufacturing,

- Doesn’t require a new machinery design for fabrication of cell (one of the important capital expenditure advantages),

- Enhanced safety (Does not catch fire on nail penetration, crushing, overcharging etc),

- Replaceable and Refillable (Lithium can be replenished on the used bilayer solid electrolyte substrate) for Li/Air and Li/S battery chemistries

- Improved cycle life when assembled,

- The use of liquid electrolytes is completely eradicated.

- The ceramic Li+ solid electrolyte substrate employed in fabricating PLC possesses high Li+ conductivity of the order of 0.3×10-3 S/cm at room temperature that acts as both separator and a Li-ion conducting solid electrolyte medium.

- Ceramic Solid electrolyte membrane is stable in ambient air and water (a surprise to the battery community),

- Ceramic Solid electrolyte membrane is stable up to 300oC, thereby eliminating thermal runaway problems (that commonly exits in traditional Li-Ion batteries),

- Good piercing strength (10N) offering a good dendrite resistance.

- NO stake pressure required to maintain Cell operation.

- Complete closed-loop operation via recovery of Li and cathode via environment-friendly recycling.

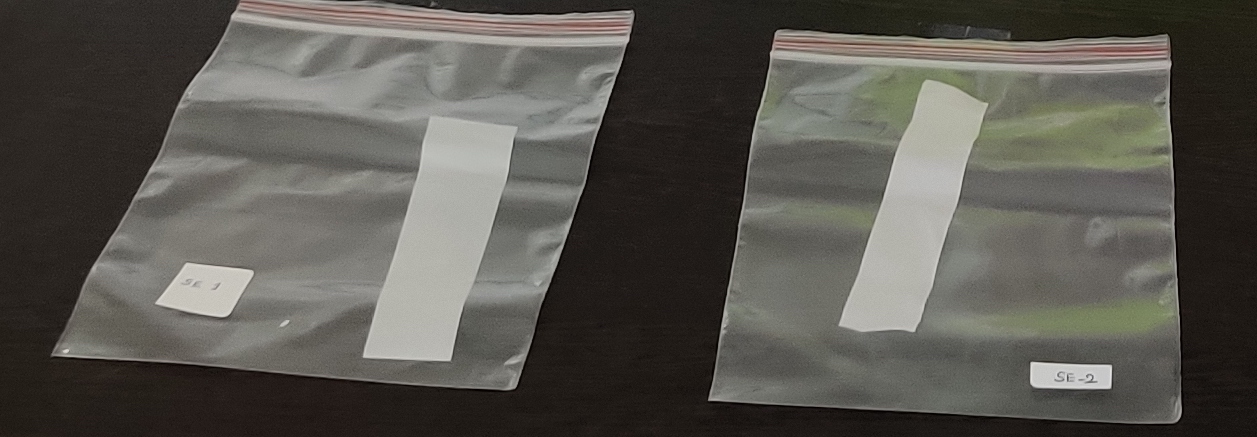

PLANAR SOLID ELECTROLYTE SUBSTRATE (Proprietary) – Ionic conductivity 0.9mS/cm AT ROOM TEMPERATURE; Ionic Transference no: 0.99

Our ASSB utilizes a Protected Lithium Metal Anode Cassette (PLC) anode, designed to offer energy densities >400Whkg-1 . Our PLC incorporates a lithium metal anode and a proprietary flexible ceramic layers (buffer+SE) as solid electrolyte (Li+)/separator encapsulated using a copper current layer yielding a monolithic cassette.

Our Solid State Battery Technology Development Centre